PETase

Or should we say PET-ace?

Need to know

The discovery of a PET-eating bacterium in 2016 and the subsequent engineering of more efficient PETase enzymes might well be the breakthrough we need to dispose of plastic waste. But will there be unwanted consequences if we launch armies of this super enzyme into our cities, rivers, and oceans?

Just like second-rate academic papers, plastics are complex, long, repetitive, and it takes decades to centuries to decompose. For example, for a plastic bottle to be gone 450 years must go by. Just imagine: if a single plastic bottle could travel back in time, it would have seen the establishing of the short-lived Roanoke Colony by Sir Walter Raleigh in 1585, and it would still be around to tell the tale.

Plastic bottles are made of PET (polyethylene terephthalate), the most commonly used thermoplastic polymer (PET counts for about 18% of all plastics). Nearly 500 billion plastic bottles are used worldwide in a single year. Not only that, but PET is also used to make plastic products such as polyester clothing and all sorts of cosmetics and food containers. With such a wide array of possible uses, plastic waste is the obvious result.

The best-known treatment methods for PET waste are recycling, landfill treatment, and incineration. But only 9% of plastic is recycled nowadays. There are a few reasons why: recycling facilities are not evenly distributed worldwide, logistics are complex and expensive, and the manufacturing of new plastics is cheaper than recycling. As for the other methods, landfill treatment causes land pollution and, of course, incineration brings on air pollution.

Fishing bacteria amidst plastics

How could the problem of PET waste be truly overcome? The answer was found by Japanese researchers in 2016 when an article in Science (written by a team of researchers led by Kohei Oda of Kyoto Institute of Technology and Kenji Miyamoto of Keio University) reported that they isolated a novel bacterium, Ideonella sakaiensis 201-F6. It seems they had literally found it among the hips of plastic dumps at a recycling center.

They discovered that these bacteria connect with each other and with PET film by appendages and deliver PET-degrading enzymes that degrade the film after 6 weeks at 30°C.

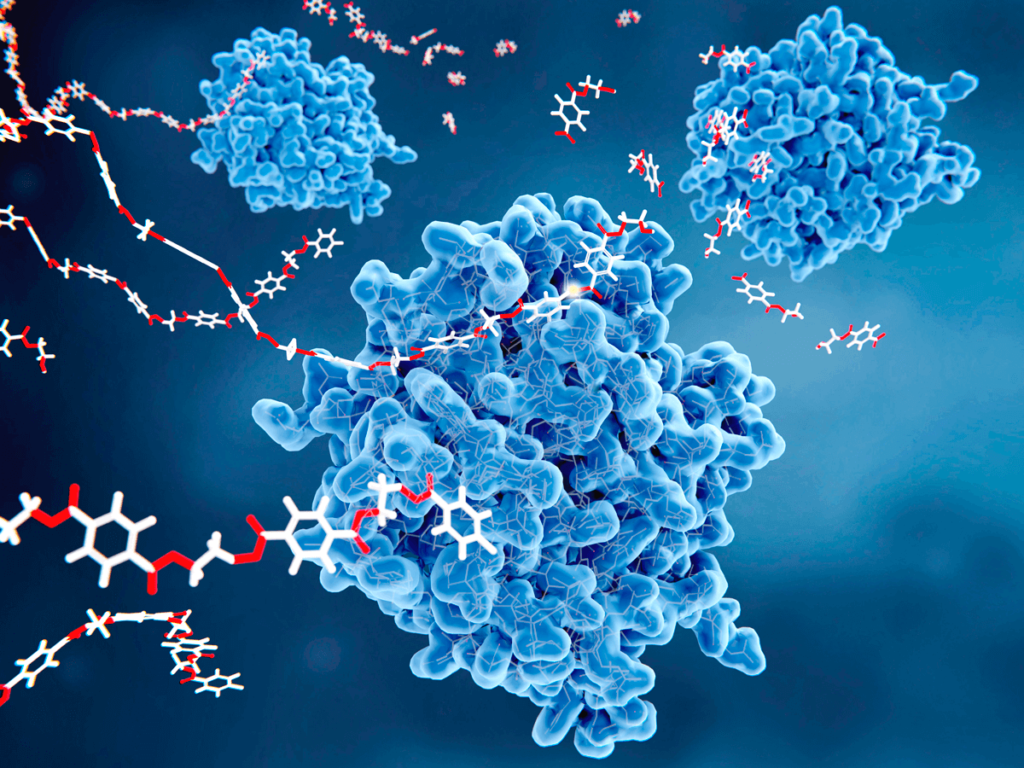

The extraordinarily useful enzymes received the name of PETase, a shortening for the complete I.D. that identifies them as polyethylene terephthalate hydrolase.

Over the past few years, new research showed that if linked together, two enzymes speed up the process considerably.

You see, PETase is just part of the equation. It breaks PET chains down into their individual units, known as MHET (Mono 2-hydroxyethyl terephthalic acid).

Then, MHETase -another enzyme-breaks MHET in terephthalic acid (TPA) and ethylene glycol (EG). The bacterium I. sakaiensis uses both subproducts.

As a result, the super enzyme formed by PETase and MHETase eventually ends up converting plastic into CO2 and water.

Time for the Labs to shine

Now here’s the pity: Ideonella sakaiensis (a Gram-negative, aerobic, and rod-shaped bacterium with motile cells with a polar flagellum) grows within the pH range 5.5-9.0 (optimally at pH 7-7.5) and at 15-42 ºC (optimally at 30-37 ºC). Its instability during long-term storage and plastic depolymerization process hinders its application in industrial-scale PET biodegradation.

But not everything is lost. New research findings show that the rate of PETase hydrolysis could be significantly increased in the presence of hydrophobin RolA. We are talking about a class of small fungal proteins with a high surface-active substance. It can spontaneously self-assemble in hydrophilic-hydrophobic interfaces.

What does this all mean in standard English? It means the chaps are full at work in the labs, giving nature a hand, so to speak.

Some of them used a structure-based, machine learning algorithm to engineer a robust and active enzyme: FAST-PETase (functional, active, stable, and tolerant PETase), which has five mutations on the active site of the original PETase, thus improving PETase degradation speed.

Some of them engineered the bacterium E. Coli to secrete extracellular PETase.

Some expressed an optimized PETase gene in the yeast Yarrowia lipolytica.

And there will be others in the years to come.